Case Study: Fog cannons resolve visible dust issues for Sunstate Cement

Dust-A-Side Australia is renowned for its dust control solutions in the mining industry, but our expertise extends beyond mines. We tailor our products and services to suit various industries, including construction, farming, gas, rail, and renewable energy. Recently, we partnered with Sunstate Cement, a major player in the processing and materials handling sector.

Sunstate Cement is a leading cement product manufacturer and supplier of high-quality cement products, selling to commercial businesses in Queensland and northern New South Wales.

Operating with a capacity to produce over 1.5 million tonnes of cement annually, Sunstate Cements’ main office and plant is strategically located at the Port of Brisbane. Whilst this location is ideal for operations, it presents challenges in terms of dust control due to its proximity to other industrial businesses including bulk cargo operations and grain producers.

The Challenge

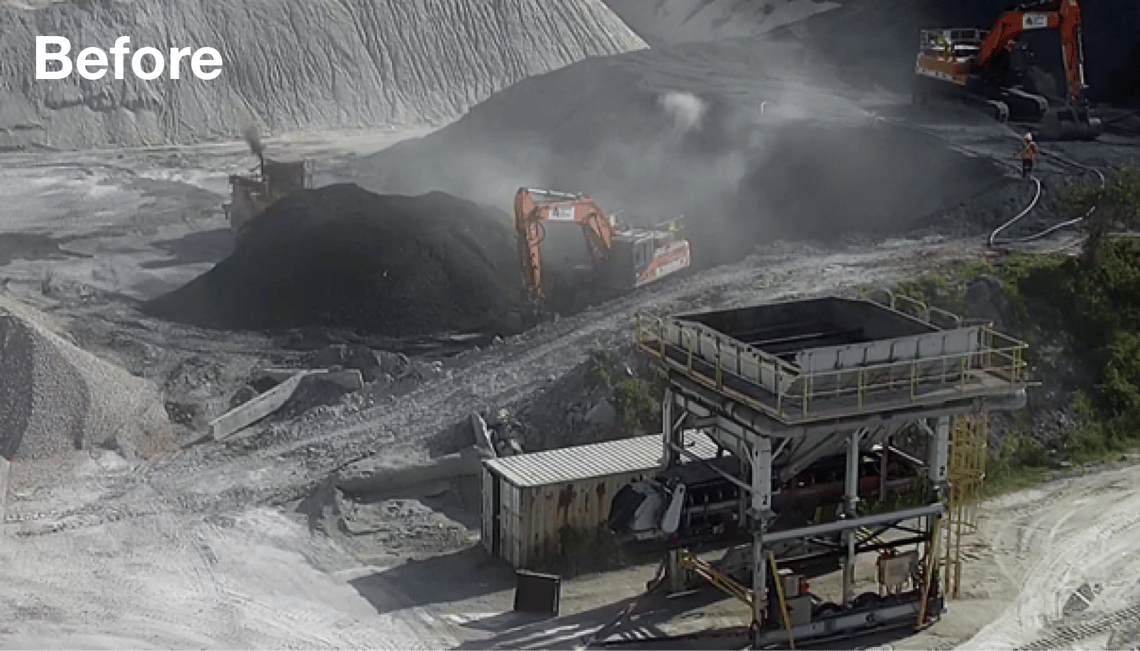

The cement plant generates significant dust during its operations. Unloading clinker and gypsum, the key raw materials for cement production, inevitably stirs up dust. Additionally, these materials produce more dust as they go through receiving systems and various manufacturing processes. Wind further aggravates the issue by picking up dust from stockpiles throughout the plant.

Sunstate Cement has health, safety and environmental responsibilities to contain errant dust and prevent it from affecting its surrounding neighbours via the wind. It was recently identified by management that, while the plant had dust control measures in place, they were not wholly effective in reducing visible dust coming from the site.

With new developments occurring in and around the port, including a major ferry terminal upgrade, Sunstate Cement sought out Dust-A-Side Australia for a more robust and targeted solution.

The Solution

A team from Dust-A-Side Australia conducted a site inspection at Sunstate Cement and evaluated the layout and operations to determine what dust control measures would be appropriate. Fog cannons were selected as the best option for a trial run and two trailer mounted units were delivered to the plant.

Fog cannons operate by pumping highly pressurised water through a series of jet nozzles, turning the water into mist through atomisation. This fine mist is dispersed through the air by a powerful fan. When airborne dust particles hit the mist, the particles are captured and the water dissipates before ever having the chance to spread.

These cannons are ideal for use in scenarios where wind is a challenge and there is a need to stop dust from spreading past a certain perimeter. They can be moved to target specific dust generation points such as at the mouth of hoppers, crushers or conveyor belts as needed. The direction of the fans, the size of the spray nozzles and the amount of water used can all be adjusted whenever there’s a change in wind direction or weather conditions.

At the Sunstate Cement plant, the two fog cannons were strategically placed near major dust generation points and moved to target different points when required. The reduction in visible dust was almost immediate once the fog cannons were switched on.

Sunstate Cement had used fog cannons in the past but found them to be ineffective. The success of this trial was attributed by Sunstate’s management to Dust-A-Side Australia's fog cannon models, which featured remote control functionality. Wind direction and weather conditions change frequently at the port. Having the ability to remotely and quickly adjust the speed and direction of the fans was found to be crucial, rather than having to rely on workers to do so manually.

Following the successful trial, management decided to install a permanent 50mm water pipeline around the perimeter of the plant. This means the fog cannons can be easily moved to different locations on-site and connected directly to the water supply.

Management have reported continued success with the fog cannons. They have also shared the details about their new dust management strategy with neighbouring businesses at the port who are also pleased with the results.

Interested in arranging a fog cannon trial?

If visible dust is an ongoing issue at your site, the team at Dust-A-Side Australia can help.

Click here to request a no obligation sales call or technical consultation.