What’s the Difference Between Dust Suppression and Dust Prevention?

Having spoken to a lot of mining operations managers and superintendents recently, Dust-A-Side Australia have come to realise that there is some confusion as to the difference between Dust Suppression and Dust Prevention

We hear comments such as: “But aren’t they the same thing?” and “Can’t we just hose the material down and be done with it?”

In this article, we’ll look at the difference between dust suppression and dust prevention, and explain why it is appropriate to use them for different purposes in different situations.

Dust control — a quick overview

There is a clear difference between dust prevention and dust suppression.

Broadly speaking there are two types of dust control systems:

- Low pressure systems ideal for preliminary dust prevention, and

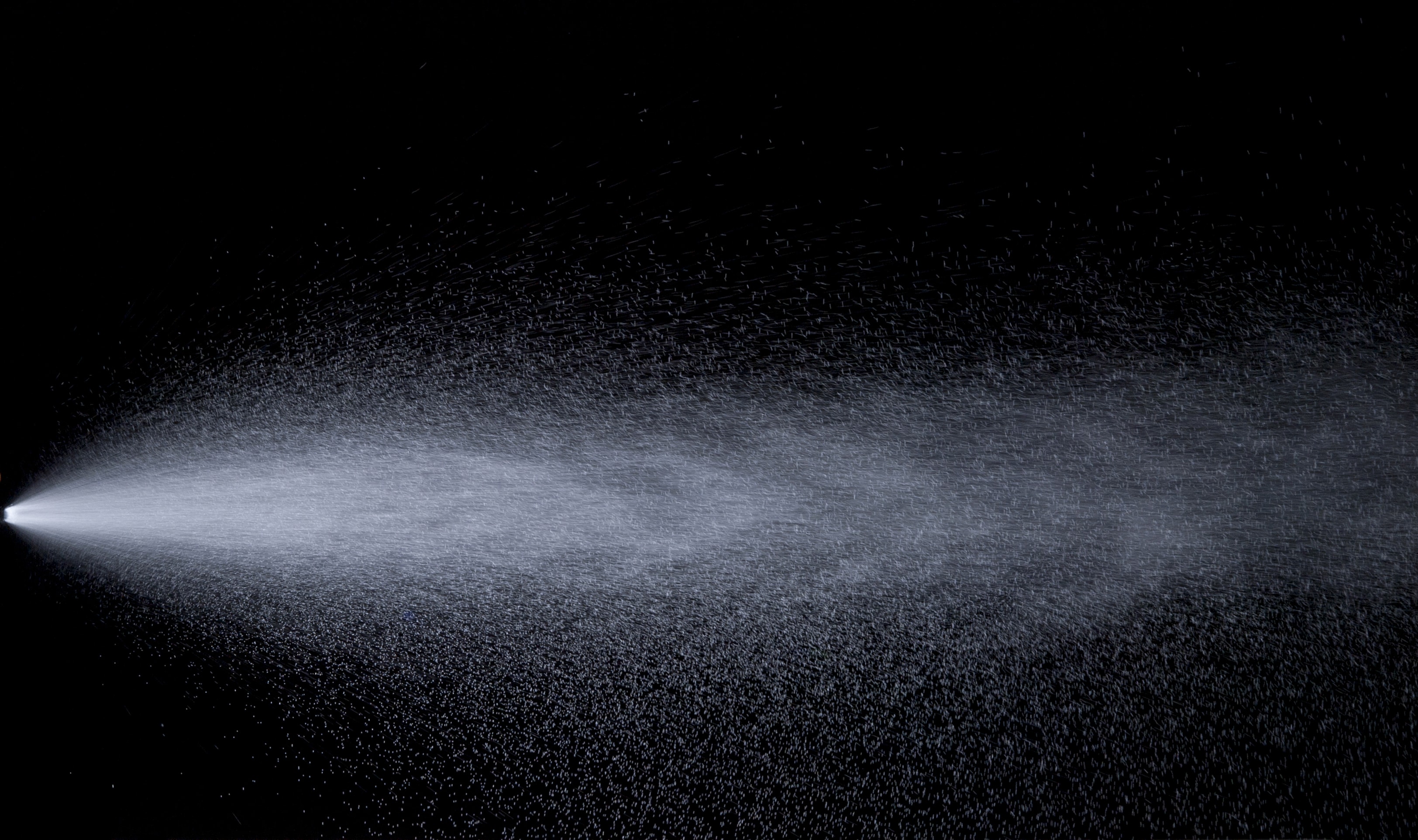

- High pressure dust suppression systems, (also known as misting systems), that settle the dust without leaving a wet, cloggy residue.

As with most things, there are reasons for/against these two dust control strategies, depending on the situation and application.

In fact, many mining operations employ both systems. We call this Total Dust Control Management.

Let’s break down the difference between dust suppression and dust prevention a bit more.

First up, a look at low pressure dust prevention systems…

Put simply, low pressure systems use large volumes of water to pre-wet the material and increase the moisture/humidity content. This is usually implemented close to the source such as the beginning of the transfer point. It will quell the coarser dust (10 microns and larger) and will reduce the overall dust on the site.

However, while there is often a real need to soak material thoroughly with a low pressure system, there can be significant downsides for the site, including:

- Increased water usage (And its associated costs)

- Dealing with runoff all over the plant

- Excessive water pooling leading to health and safety risks

- Increased corrosion of conveyors and other infrastructure as water is carried through the entire plant

- Clogged up chutes, and

- Clogged up conveyors

Those issues aside, you also have to think about the harmful dust that you can’t see. What about the microscopic specs that are less than 10 microns?

That’s where high pressure dust suppression systems come into play.

High pressure dust suppression systems…

These systems use lower volumes of water at high pressure (more than 50 bar) to add a fine atomised mist to the air to subdue miniscule airborne dust particles that are less than 10 microns.

This is the more dangerous respirable dust that can lead to:

- eye irritation

- vision impairment

- environmental degradation, and

- major health issues including Black Lung Disease (pneumoconiosis).

There are also a host of other reasons why high pressure dust suppression is a preferred option for dust control, particularly when it isn’t possible or practical to pre-wet material.

One of these is that the overall use of water is decreased, due to the fact that moisture is added to the air when suppressing dust and not to the material itself.

This means that high pressure dust suppression systems have fewer short and long-term peripheral issues.

In short, they reduce the likelihood of blockages in the downstream materials handling process caused by cloggy, wet material.

With high pressure dust suppression systems configured to your specific needs, you can process and handle material at any time, confident that dust will NOT be an issue.

High pressure dust suppression systems are ideal for the following plant and process areas:

- Tipping Areas

- Conveyor transfer points

- Surge bins

- Crushers

- Screens

- Stockpiles

- Stacking and reclaiming

- Transfer chutes

- Train Loud-Outs

- Port Terminals

- And more

Dust suppression for coal and other fine ores

Some hydrophobic materials such as coal and other fine ores bring specific challenges. In these situations, the effectiveness of a high pressure dust suppression system can be enhanced by products such as HydroWet, a concentrated surfactant specially formulated by Dust-A-Side Australia to improve the wetting ability of water.

HydroWet lowers the surface tension of water particles, which in turn enables the water particles to attract dust particles to them, via agglomeration.

For effective dust suppression with coal and other fine ores, the selection of spray nozzles is another important issue.

For effective dust suppression, it is important that the water droplets are equivalent in size to the dust particles leading to smaller water droplets (between 5 and 10 microns); if the droplets are too large, the fast-moving airborne dust will simply flow around them.

The correct nozzle, when combined with HydroWet will ensure that much higher levels of dust suppression can be achieved, with greatly reduced use of water on the site.

We hope this article has been useful to you in explaining the difference between Dust Suppression and Dust Prevention.

Like to know more about our Total Dust Control Management systems?

A well designed and properly installed high pressure dust suppression and low press dust prevention system is an economical long-term solution that, with regular maintenance, can provide years of trouble-free performance.

Dust-A-Side Australia can help you get the performance you need for your specific environment and operating conditions with our Total Dust Control Management systems.

For more information and advice about our systems, or to discuss anything to do with dust control, speak to one of our dedicated engineers today. Call 1800 662 387 or contact us.