Case Study: Reducing Airborne Dust by 82% on a Mine Services Road

Key Findings from a HydroTac Trial Project

Introduction:

In a recent trial project at an open-cut mine, the implementation of our specialised dust binder product, HydroTac, has yielded significant cost savings and productivity increases.

This summary highlights the key findings and outcomes of the project, showcasing successful reductions in airborne dust levels, a decrease in equipment usage as well as improved road conditions. Let's delve into the details.

Firstly - what is HydroTac?

HydroTac is a specially formulated biodegradable binder that can be used on haul roads, access roads and other exposed surfaces as a spray-on dust control treatment. Totally organic, it has no corrosive chloride compounds and is environmentally friendly and readily biodegradable.

Working as a hygroscopic crusting agent, this lignosulphonate based dust control product helps mines to reduce water bowser usage for dust control purposes and has been shown to significantly reduce water cart operating hours and fugitive dust levels.

Scope of the project

The open-cut mine approached Dust-A-Side Australia, looking to trial the effectiveness of our HydroTac formulation on two separate roads which were yet to be established.

Areas to be treated:

- Mine services road – 650m x 15m = 9,750m2

- Heavy vehicle access road and intersection – 1300m x 50m = 85,000m2

While these new roads were being established, HydroTac was built in with a scarifying blade to an average depth of approximately 50mm. After establishment, the roads had one application of HydroTac per 24 hrs with a water cart. Ongoing maintenance and repair work after road damage was completed with a Dust-A-Side Australia grader and water cart.

The data to report the effectiveness of the HydroTac applications was measured by analysing:

- Dust monitor results - data was collected as a 4-day group to compare pre-application and post-application dust levels across both roads.

- Imagery - a camera with a motion sensor was set up along with the dust monitor.

- Product usage levels - this data indicates the time and frequency of the applications of HydroTac (once per day)

Results

Reductions in fugitive dust

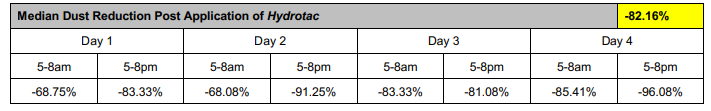

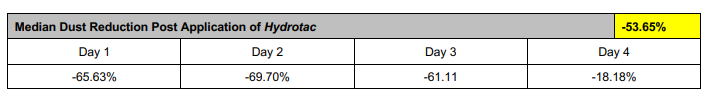

Efforts to reduce fugitive dust were highly successful. Comparative analysis revealed a remarkable average dust reduction of 82.16% on the services road and 53.65% on the heavy vehicle access road post-application of HydroTac. It is worth noting that these levels are expected to decrease even further if HydroTac is applied multiple times a day, as per the typical requirement.

Mine services road:

The information presented in the below table shows the dust levels at the services road before and after the application of HydroTac. The data was collected over two, four day periods between 5-8am and 5-8pm, as these times best illustrate the highest traffic in the area, corresponding with shift change. A dust monitor was placed in the area to record dust levels as well as a motion camera to capture pictures of any vehicles creating significant airborne dust.

Heavy vehicle access road:

The information presented in the below table shows the dust levels at the heavy vehicle access road before and after the application of HydroTac. The data was collected over two, four day periods between 5am and 6pm, as these times best illustrate the daytime operational traffic in the area. A dust monitor was placed in the area to record dust levels as well as a motion camera to capture pictures of any vehicles creating significant airborne dust.

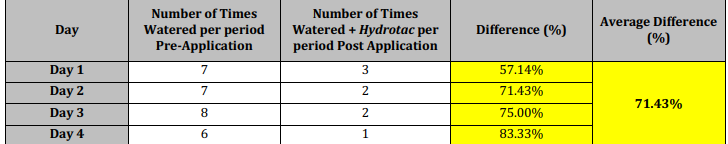

Reduction in equipment usage

The implementation of HydroTac resulted in a notable reduction in equipment usage. Specifically, the trial project showcased a significant reduction of 71.43% in equipment usage on the heavy vehicle access road.This reduction not only enhances operational efficiency but also has potential economic and environmental benefits.

The information presented below shows comparative data taken from the camera set up at the heavy vehicle access road. The motion detecting camera was used to count the number of times the road was watered with a water cart both pre and post application of HydroTac

Enhanced road performance and safety

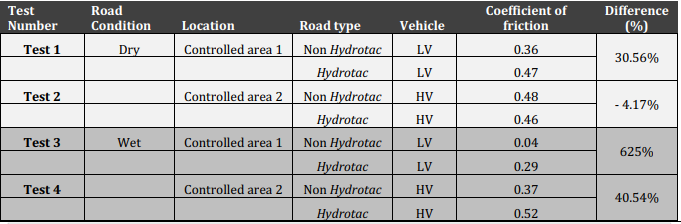

In addition to dust monitoring, Dust-A-Side Australia carried out friction testing on the treated roads, utilising testing methods from Australian Diversified Engineering (ADE). The equipment used was an ADE monitoring app, a light vehicle (Toyota Hilux) and a heavy vehicle (CAT 740 water truck). The friction test was conducted by fully applying the service brakes to bring the vehicles to a complete stop in both wet and dry conditions, with the monitoring app logging all the data.

The results of these were highly encouraging. In three out of the four tests, the coefficient of friction was higher on the HydroTac treated areas compared to the non-treated areas.

The coefficient of friction is an inter-relationship between;

- Friction supply - the available friction where vehicle tyres meet the haul road surface, and

- Friction demand - the required friction to operate the vehicle for a given circumstance on a road

If the friction demand at a section of road is higher than the friction supply, the vehicle operator will be unable to safely negotiate that specific geometry of road, and the outcome will most likely be an uncontrolled/unplanned movement causing damage, injury or, in the worst instance, death.

The intent of these tests was to illustrate that applying HydroTac to the road surface does not result in significantly lower levels of friction that could lead to unsafe road conditions

The test results are presented in the table and graph below.

These results indicate that the friction supply has increased over the friction demand in the tested sections, meaning there was improved braking performance in both wet and dry conditions, further enhancing safety.

It's important to note that these results are specific to the tested areas and vehicles used, and variations may occur on different roads due to factors like geometry.

Conclusion:

The HydroTac trial project has proven to be a resounding success, meeting all success factors for key performance indicators.

By implementing HydroTac, the project reduced fugitive dust, created safer working conditions, optimised equipment usage, and enhanced road performance.

These findings underscore the effectiveness of HydroTac as a valuable road treatment product, paving the way for safer, more efficient, and environmentally friendly road infrastructure in the future.