Mine site dust control programs - building confidence and certainty with a credible provider

It is extremely common for mines to implement an independent, do-it-yourself program for dust control to avoid perceived risks around bringing in new service providers unfamiliar with their operations, or repeating prior experiences with poor performing suppliers.

As an alternative approach, engaging with an experienced dust control service provider can result in significant benefits for the mine. In fact, engaging with a reputable supplier should provide an experience that features security of product supply, performance guarantees, service support and enabling technologies and processes that provide control and predictive scheduling for future events. The mine does not have to reinvent the wheel and waste limited resources trying to implement an effective dust control program when specialists are capable of doing so.

Dust-A-Side Australia writes extensively about the merits of using outsourced dust control management services – especially in haul road maintenance applications.

This blog dives further into two of the features mentioned of reputable dust control suppliers with (i) providing security of product supply and (ii) using enabling technologies to provide controls and predict future planning events. These are particularly important features to explore in current times where supply chains are stretched and mines increasingly look to technologies to help automate controls and deliver efficiencies.

Certainty and consistency of supply of dust control products

Especially now in our COVID-19 affected world, mines want the best assurances from their suppliers that their supply chain is as robust, ethically sourced and reliable as possible.

If a vendor’s supply chain for dust control products is impacted by global events and supply becomes intermittent or costs fluctuate wildly, this can have a significant impact on the effectiveness of the program and on the broader productivity of the mine’s operations.

Unfortunately, many dust control suppliers lack both the real-time monitoring technology needed to plan for future orders and avoid product shortages as well as the capability and capacity for local onshore manufacturing to reduce exposure to supply chain costs/risks offshore.

As a multi-product technology supplier to the Australian mining sector, Dust-A-Side Australia represents certainty of supply through breadth of product offer and economies of scale in the sourcing and on-shore blending of specialised dust control polymers. Through its parent group of companies, Dust-A-Side Australia also enjoys direct access to Australia’s largest importer of raw bitumen for the local manufacture of its effective and industry leading haul road bitumen emulsion DAS Product. In addition to dust free environments, Dust-A-Side Australia clients enjoy consistency of supply and comparatively stable pricing.

Furthermore, mines can best ensure consistency in their supply of dust control products by engaging dust control providers who offer systems that provide predictive analytics for inventory management and product re-ordering so that product wastage, supply lag or shortages don’t occur.

Why real time monitoring of dust control product usage is so important

It's critical in dust control and haul road surface improvement programs that the use of dust control products are controlled and aligned with a site specific maintenance management plan.

As this article stated in the beginning, uncontrolled, do it yourself dust control programs are common in the industry and typically lack the following:

- Real time reporting of dust control product volumes on site, frequency, rate and time of watercart dosing. Often clients only have delivery records to site to go by. But this doesn't help the client understand how the product is used once it is on site.

- A plan or direction on where and when to spray required roads/areas.

- Storage and set up of dust suppressants separate from the water supply, particularly if there’s only a single water fill point. If there is no separation of product from the water source, a mine loses control of where the suppressant is sprayed.

- Metered product dosing pumps for controlled, consistent dosage of products into water carts and variable presets according to water cart tank capacity, seasonality or application (e.g. light vehicle access roads vs heavy vehicle haul roads).

- Early alerts on low product storage volumes and product reorder reminders.

Without real time product management and monitoring systems, mines run the risk of delivering uncontrolled dust control programs that waste product with intermittent supply,

For example, in the absence of real time monitoring, the mine may only realise once product tanks are empty that operators have inadvertently been overdosing watercarts and using more product than planned or that the wrong watercarts have been using the product by mistake. In these circumstances, the mine is caught off guard with no product to continue its program and time and money is wasted trying to chase additional supply from a vendor who is also none the wiser.

Other common issues that can be missed without the real time information provided by telemetry systems are leaking storage tanks or failed dust control product pumps.

Such problems need to be identified immediately so that they can be efficiently rectified in order to save a mine both costs and downtime taken to conduct repairs.

Dust-A-Side Australia’s telemetry product monitoring is a critical tool for addressing the points above

Our telemetry systems use battery and solar powered 3G connections to provide real-time data from dust control product storage tanks on site.

By monitoring and reporting on the following via secure website platforms, clients can get real time readings on:

- Tank volume levels (% capacity used and litres remaining)

- Number of product loads taken

- Average volume of loads

- Product volume used

- Automated alerts when storage volume reaches reorder/redelivery levels

This data and reporting helps us deliver the following benefits:

- Guidance and redirection of use of products if volumes are too high or too low

- Maintenance programs are kept on track with expected product use and watercart loads per day

- Future product deliveries to site are timed for an uninterrupted supply chain

- Internal quality standards for project performance and deliveries are improved through our accredited solutions.

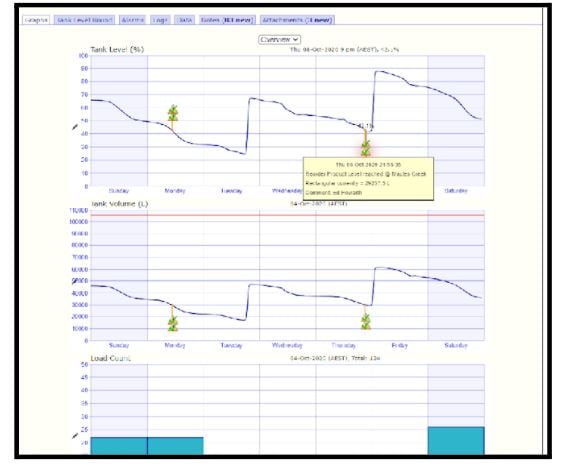

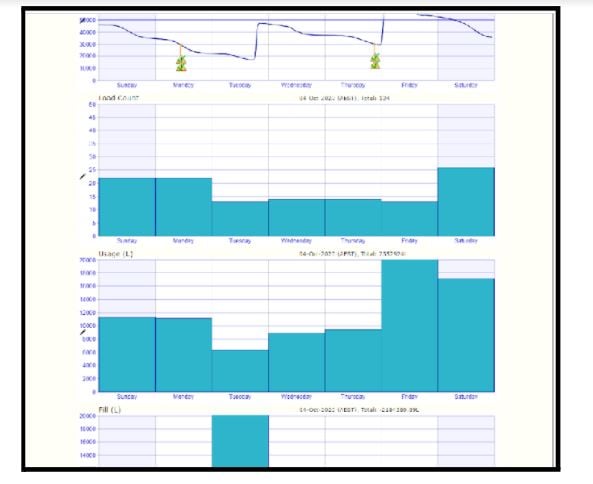

The below screenshots provide an example of just some of the analytics we are able to measure for our clients. Units of measurement are dynamic and we can drill down to hours in a day, days in a week (as shown), days and weeks in a month etc.

Tank volume, level and reorder triggers:

Load counts/product use:

Load counts/product use:

Interested in learning more about our on-site telemetry and dust control services?

Operating since 1973, Dust-A-Side Australia is an experienced supplier to mining operations in Australia and across the world.

We are a major supplier and onshore blender of organic polymers for dust suppression and binding in addition to manufacturing dust control emulsions within Australia.

Our shareholder group is the largest importer of raw bitumen with production plants in most capital cities.

Dealing with Dust-A-Side Australia ensures you are dealing with highly trained dust control experts who understand how mines work and have the experience to work safely on-site.

To request a no obligation technical consultation and dust report, simply click here.