Preventing dust diseases with dust suppression

One of the biggest hazards for workers across mining, construction and bulk material processing is actually something quite small…fine dust particles.

Breathing in dust and long-term exposure to dust has been proven to cause mining related dust diseases that affect the eyes, lungs, throat and even the nervous system.

Fugitive dust has numerous generation points throughout an underground or open-cut mine including haul roads, stockpiles, conveyors and hopper bins. Processing activities such as drilling, charging and blasting are also major contributors to air borne dust.This makes dealing with fugitive dust a whole-of-site problem which requires a highly effective solution.

In this article, we’ll take a look at the dangers of fine dust particles to the health of workers as well as how dust suppression systems can be used to reduce the risks of dust diseases.

The dangers of respirable dust

Different sizes and types of dust can have different health effects on those who breathe it in. The smaller the dust particles, the greater the potential for causing serious harm to people’s health.

Inhalable dust particles are less than 100 microns in diameter and are completely visible.

Whereas respirable dust particles are smaller than 10 microns and are invisible to the naked eye.

So just because you can’t see any dust in a mine site, doesn’t mean there isn’t any there.

Unlike inhalable dust which gets mostly gets trapped in the mouth, nose and upper respiratory tract, respirable dust has been shown to penetrate deep into the lungs.

Prolonged exposure to high levels of respirable dust can lead to irreversible health effects such as:

- Ongoing coughing and shortness of breath

- Pneumoconiosis (lung dust diseases such as “black lung” and silicosis)

- Respiratory failure

It’s important to note that workers in both underground mines and open-cut mines are at risk of developing dust diseases. Anyone who is exposed to coal, silica and other types of dust needs to be aware of the potential dangers.

Unfortunately, in Australia, there has been a resurgence in cases of black lung in recent years.

This is a result of a lack of adequate dust control measures being implemented in mines. Additionally, an increase in the number of cases of silicosis has drawn wide-spread concern within the mining industry.

Reducing exposure to respirable dust

Traditional measures for reducing exposure to mining dust include:

- Use of Personal Protective Equipment (PPE)

- Use of Personal Dust Monitoring Equipment

- Ensuring adequate ventilation

- Limiting worker exposure using administrative actions (job rotation, automation and following best practices in operator positioning)

- Use of low pressure water systems to spray dust generation points with water and pre-wet materials

Despite these measures being widely practiced in mines, there are limits to their effectiveness as none are able to sufficiently eliminate respirable dust particles in the air.

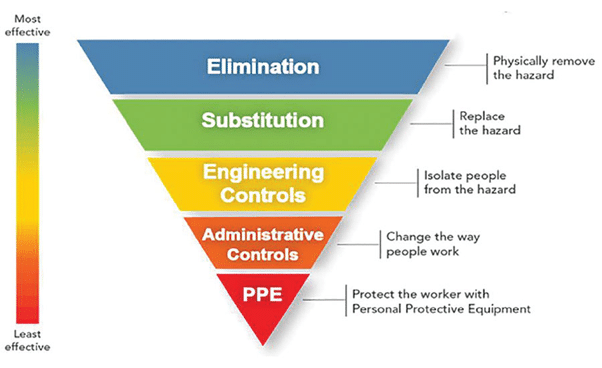

Consider the “Hierarchy of Hazard Controls” diagram which is shown below. In this framework, strategies for controlling risks are ranked from the highest level of protection and reliability to the lowest.

This diagram can be used to grade the effectiveness of common measures used to reduce exposure to respirable dust in mines.

The very least effective measure is the use of PPE which should be used when other control measures are not practical and as the last line of defence.

Administrative controls are most effective when used in conjunction with other more reliable methods and should not be relied on entirely.

The most effective strategy in dealing with respirable dust will always be to physically remove the hazard as much as feasibly possible.

This is where dust suppression comes in.

Dust suppression systems reduce the risks of dust diseases

Dust suppression systems are misting systems that use low volumes of water at high pressure (more than 50 bar) to add a fine atomised mist to the air to capture and subdue airborne dust.

Unlike low pressure systems which use large volumes of water to pre-wet materials, high pressure suppression systems are specifically calibrated to capture respirable sized dust particles (< 10 microns).

The secret to successful dust suppression is ensuring that the atomised water droplets and the target dust particles are of equivalent size. This allows the droplets and the dust particles to combine and fall to the ground, assisted by gravity. If the droplets are too large, the fast-moving airborne dust will simply flow around them.

High pressure dust suppression systems can reduce levels of respirable sized dust by 80%+. This make dust suppression a highly effective strategy in preventing the risk of workers developing mining related dust diseases.

Want to learn more about reducing respirable dust at your site?

As Australia’s leading provider of dust suppression systems, Dust-A-Side Australia understands that the risks of respirable dust can simply not be ignored.

To learn more about our custom-built dust suppression systems, click here to request a free on-site inspection and preliminary dust report. Or you can get in touch by calling 1800 662 387.